Steve Loucks – Easy Way to Adjust Glazes

Here’s a great video that’s absolutely worth the watch!

Books for Glaze Prospectors

Without a doubt, Pioneer Pottery is the best resource for you diggers out there. Micheal Cardew was an absolutely incredible potter and glaze wizard. Here’s the book summary from Amazon:

You can find it here.

Pioneer Pottery is one of the classic texts in ceramic literature. Its author, Michael Cardew, was one of the seminal figures in British ceramics and this book, written partly in response to his time spent in Africa, has influenced generations of potters around the world.

As one of the early and influential figures in British ceramics, Michael Cardew was asked in 1942 by the Crown Agents to go to Nigeria to set up a pottery training center. It was his experiences there, as well as his previous time spent in the Gold Coast, that formed the basis for this book. In addition to discussions about the basics of clay and glaze materials and their properties, Cardew shows how to make pots in the Kwali, Jebba, Vume, Ilorin, and Hausa traditions of western Africa. This book is the first book to discuss all aspects of the pottery making process from materials through marketing. Michael Cardew found it necessary to find out and do everything for himself, and this is what lies behind this book. The consequence is that it is filled with a sense of discovery and firsthand knowledge.

A second amazing book is Glazes From Natural Sources. I like Sutherland’s perspective, and his instructions on building a home made ball mill and pugmill are super interesting. Although US buyers will probably find this one a little more expensive, it’s a great resource to have. Here’s the Amazon summary:

Glazes from Natural Sources: A Working Handbook for Potters, 2nd edition

Any real education in ceramics must involve, from the outset, an appreciation of the source materials—the rocks around us. While good, throwable clay may be a regional commodity, there is no part of the world that will not yield potential glaze materials in abundance. Potters therefore need to know how to exploit the special properties of local rocks quickly, reliably, and methodically. This new revised and updated version of Brian Sutherland’s classic book on making glazes from natural sources explains how to locate glaze material and construct, test, and use the glazes created.

Glazes from Natural Sources discusses rock types and other likely sources of supply, the making of test pieces, and the use of blend systems and constructions. The author also clarifies the Seger system of glaze presentation for those who, like himself, have found it difficult to grasp and apply. He covers, and supplies, formulae for glazes for all temperatures—from raku to stoneware and porcelain—and includes sample recipes. The book emphasizes careful planning and control to ensure results that are repeatable. This makes the science behind making glazes from natural sources both understandable and feasible.

Glazes from Natural Sources is fully illustrated, with diagrams of techniques demonstrated as well as images of the finished works of potters to show the results of these natural glazes. First published in 1987, this book is considered a classic by ceramicists. This edition includes a new chapter by glaze expert Nigel Wood.

The Potter’s Cast

Here’s a Podcast I did at NCECA! Check it out if you’ve got some time.

Turning Wild Rocks to Glaze | Matt Fiske | Episode 527

You can also listen here.

Continue reading “The Potter’s Cast”

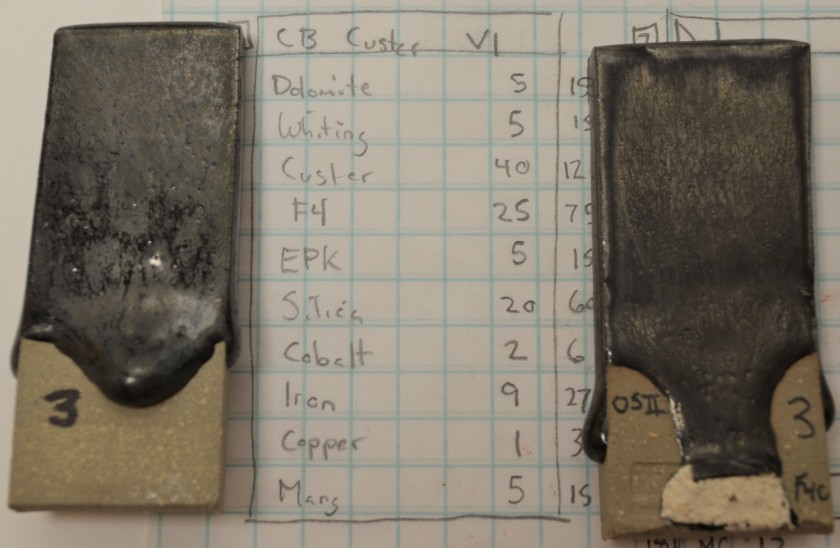

Limestone Black Glazes

Not exactly Oil Spots in the truest sense, these two variations were concocted and tested along with the rest of my oilspots glazes. Both of these recipes utilize some local dolomitic limestone I found and incorporated into the recipes. If you want to re-create these, using a mix of 1/2 and 1/2 Dolomite and Limestone will get you very close.

BluePotter on Youtube

Thrown and Stamped Fish Cup

Cobalt Black Variation

Here’s one that’s a bit of a kitchen sink: Lots of iron, manganese, cobalt, and copper.

Voulkos, Mason, Soldner. 1956

Oilspot Firing Schedules

Here’s my Lava Oil spot firing schedule, which always looked best fired in a neutral/oxidation atmosphere in a gas kiln.